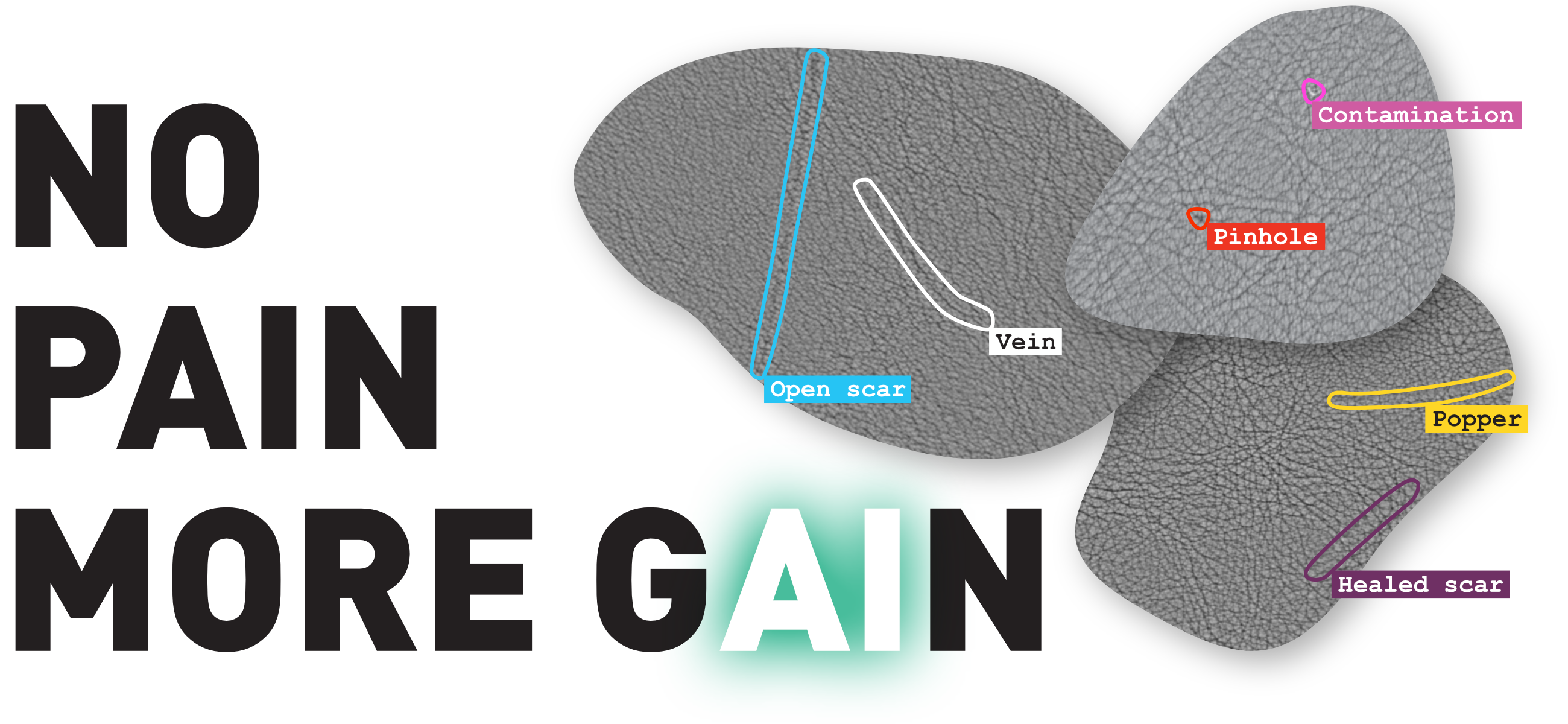

HOMIRO line is an AI‑powered modular defect detection system designed for precision and efficiency in the leather industry.

Engineered for versatility, the system adapts effortlessly to widths from 1 to 4 meters, fitting seamlessly into any production line. Perfect for tanneries and brands across automotive, furniture, and fashion industries, it handles all major leather types — from WW/WB and Crust to Finished leathers such as (Semi-)Aniline, Split, Embossed, and Nappa.

Equipped with a conveyor belt, HOMIRO automatically scans hides within seconds. The system’s robust performance has been proven by international leather brands operating three shifts a day, six days a week for years. By combining intelligent image analysis with powerful data processing, HOMIRO delivers detailed DXF files and comprehensive analytics, providing all the information needed for optimal sorting, grading, cutting and yield optimization.